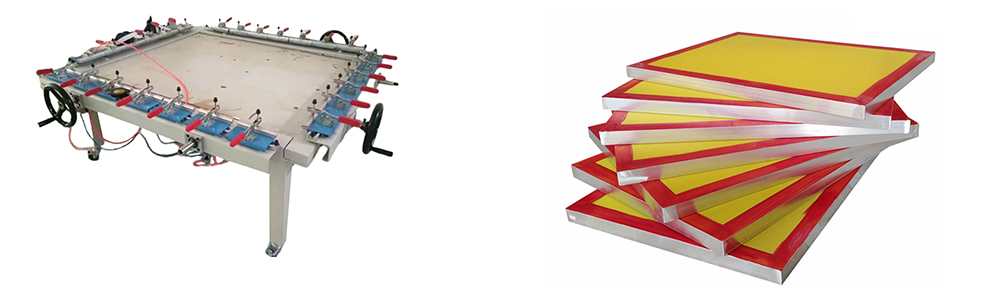

Massive Selection for Manual Screen Press - Stretching machine-N type – Jiamei

Description

| JM-ST-N90120ü | JM-ST-N120150 | |

| Automatic Grade | manual | manual |

| Max stretching size | 900mm*1200mm | 120mm*1500mm |

| Min stretching size | 600mm*600mm | 600mm*600mm |

| clamps style | Double rubber-coated clamps | Double rubber-coated clamps |

Advantages

-Push frames by pneumatic

-Stable tension strong frame work

-Push frames by pneumatic

-Stable tension strong frame work

-Double rubber -coated clamps

-Easy Frame Size Adjustment

-Corner Softening Capabilities While Under Tension

-Compatible with Essentially all Frame Types

-Stretches Directly from the Bolt of Fabric

-Utilizes a Wide Locking Bar for Easy Use

-No Special Training or Tools Required

-Maintenance-free Design

Application

It is used for assembling screen printing plates and stretching screen mesh.

Operations

1. Put the screen frame on it, the upside must be the ragged face.

2. Adjust the height of the frame, 0.04″-0.08″(1-2mm) higher than the baffle.

3. Keeping the hand-wheel in the inside of the screw rod will assure better stretching effects.

4. Coat screen adhesive, not to thin and not to thick.

5. Stretch when the adhesive sticks hand a bit.

6. Coat the adhesive again after well stretched.

7. When the adhesive solidifies completely, then the screen stretching appliance can be dismantled.

Packaging & Delivery

Massive Selection for Manual Screen Press - Stretching machine-N type – Jiamei Related Video: