requirements

1 appearance

1) Pitting points, bubbles, depressions, bulges, impurities and stains with a diameter greater than or equal to 0.05mm are not allowed at the cutting edge.

【 Understanding the Main Points 】

The position of the blade is the key part to complete the screen printing process, which affects the image quality, especially when the screen printing precision products and high resolution products.If the diameter is greater than 0.05mm on the screen image surface will appear above or below the normal ink line.

2) Scratches with a depth greater than or equal to 0.03mm, a width greater than or equal to 0.05mm and a length greater than or equal to 5 m are not allowed on the surface.

【 Understanding the Main Points 】

Exceed the required value, screen printing will appear after the corresponding size of the impact of the graphics imprint.

3) Blade flatness is less than 0.08%.

【 Understanding the Main Points 】

When using a squeegee with a length greater than 80 cm, the requirements on the flatness of the cutting edge begin to be strict, and the requirements on the flatness also increase with the increase of the length.This screen printing in large areas of products, such as ladder wall, sample wall, advertising, car and ship interior decoration is particularly prominent.

2 Physical properties

1) Hardness tolerance

Shaw hardness HA tolerance ±2.

【 Understanding the Main Points 】

Squeezer hardness is one of the technical indicators of its physical properties, different hardness of squeezer applied to different products, in order to meet the needs of different products in many fields, manufacturers have come up with a variety of products, models and different series.The Shahs hardness HA tolerance is ±2, which can effectively hoop the requirements of the manufacturer on the scraping hardness of the unit.

2) Wear resistance

Akron abrasion is no more than 0.06 cm3/1.61 km.

【 Understanding the Main Points 】

The abrasion resistance means that the volume of the sample worn off for each 1.61km journey on akron tester should not be greater than 0.06m ‘.

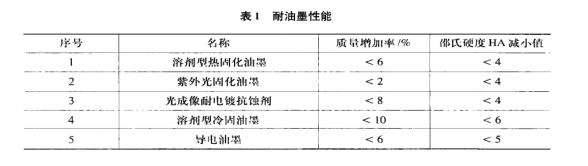

3) Chemical resistance

【 Understanding the Main Points 】

In the squeegee so that sichuan and a variety of ink, paste, paste and solvent contact.After years of improvement and development, such as adding quantitative plasticizer and additives in rubber, the chemical resistance of the squeegee has been improved to some extent.It has been proved in production practice that polyurethane squeezes have good chemical resistance but not 100% solvent resistance.Because squeegees are organic synthesis, so squeegees encounter organic solvents will be dissolved, the squeegees have offensive ink and solvent selected 5, basically including the solvent and ink to squeegees attack (dissolved) varieties, and then in the aid and oil silting were divided for 24 h immersion tank chemical resistance test.