Production technology of electrode mesh plate

The screen plate of screen printing consists of screen frame, screen and mask pattern.The screen is stretched on the screen frame, and then coated with mask graphics, using photographic etching method to produce the graphics on the screen.

screen frame

The screen frame is used to fix the screen, and the relative position between the screen and the printing base is fixed during screen printing.

1. Selection of screen frame types

According to the stretching network, the frame has fixed and stretching two categories.Battery industry mostly USES fixed mesh frame.When stretching the network, stretch the screen with the network machine to a certain tension, and then glue the screen to the frame, until the binder dry and tight backup.

2. Screen frame size and number

The screen frame is mostly made of hard aluminum and aluminum alloy, in order to withstand the tension generated by the stretch network, the surface of the bonding screen requires high flatness, about 0.04mm×150mm×150mm;The screen frame size is generally 2 times the size of the substrate, so the general battery size is 150mm, that is, the substrate area is 150mm×150mm, the screen frame mouth area is about 300mm×300mm.

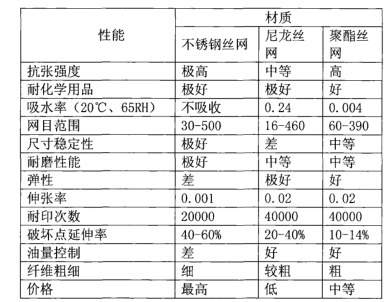

screen mesh

There are many kinds of screen printing mesh, according to the weaving structure can be divided into flat weave and oblique weave.Flat screen is the thinnest, but prone to deformation, short service life.Oblique – woven screen printing has certain limitations on the electrode pattern.

The thinnest line width of the wire mesh printing electrode pattern is limited by the wire mesh diameter and the woven mesh.The theoretical minimum width is equal to the mesh width plus two screen diameters.

Stretch mesh

The tension naetwork is to tighten the screen to a certain tension, and then bond fixed to the screen frame.Stretcher is the key technology of screen plate making, which has a very important influence on the printing quality.When stretching the network, pay attention to the control of the screen pull, control the tension of the measurement.In the process of making fine mesh, the screen needs to be repeatedly stretched.When making a new screen, the screen needs to be stretched repeatedly so that its tension reaches the desired value and stabilizes within this range.After the screen bond fixed to the frame, to let it stand dry, to achieve stability, suitable for this process is conducive to the use of the screen stability.

After the completion of the screen network, screen production has entered the last link, that is, the printing of graphics.According to the actual needs, set up the screen graphic you want to print, and then print the mask graphic on the stretched screen according to the graphic.The main process is: screen cleaning treatment, photosensitive adhesive coating, exposure, development and washing, quality inspection.

1) Cleaning treatment

Screen before coating photosensitive adhesive, need to be cleaned, out of oil, dust and other dirt, in order to ensure that the photosensitive adhesive coating uniform, good.Use appropriate cleaning agent for fine processing, the finished screen should be hydrophilic.

2) Coated with photosensitive adhesive

There are direct emulsion platemaking and direct/indirect platemaking (film film).The mask produced by direct method has good clarity and high printing resistance.The edge of the mask produced by film film is clear, the thickness can be set according to the need, and the price is expensive.To ensure the process reliability, wipe the film with an antistatic cloth before sticking the film.Both the emulsion and the film should be thoroughly dried to ensure exposure.

3) exposure

To ensure the quality of exposure, there should be very accurate process control, must use a stable light source, suitable time exposure processing.The process parameters must be very mature for good exposure operation.

4) Development and flushing

Through the control of water temperature, water pressure, etc., flush printed screen graphics.

5) Quality inspection

The screen made of quality inspection, including the screen tension, strong bond, etc., and printed screen graphic integrity test, to determine that there is no missing printing, hole blocking and other quality problems.