People familiar with screen printing should know that making screen frames is very important for the printing process. The quality of screen printing depends on the quality of a screen frame.So how to make it?

People familiar with screen printing should know that making screen frames is very important for the printing process. The quality of screen printing depends on the quality of a screen frame.So how to make it?

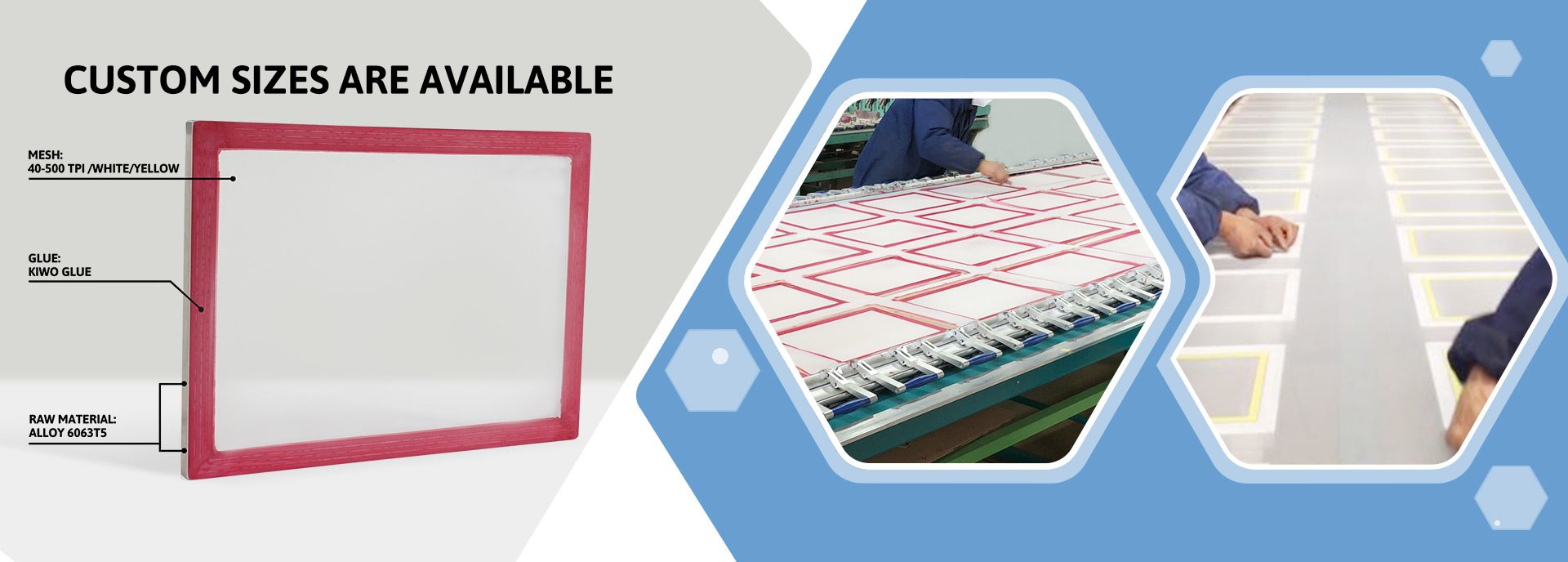

Step 1: Select mesh and frame

According to different requirements of the substrate, such as the accuracy of different, to the specific choice of mesh yarn and frame, this is very important.

Step 2: Polish the frame.

This step is very necessary, mainly to make the silk screen mesh and the frame better.

Step 3: stretch screen printing mesh

Stretch the screen printing mesh yarn according to the required strength of the frame. When the force is reached, stick the screen printing mesh yarn to the mesh frame on the side where the adhesive is applied. Wait for the adhesive to dry and cut it according to the requirements. .

Step 4: Mesh to ester

In order to make web yarns more oil-soluble, care must be taken to apply some de-esterification agent to the stretched frame to achieve this goal.

Step 5: Drying

Screen printing screens are sizing and dried.

Step 6: Stereotype

The first exposure of the screen, the flushing, and the correction of the error were performed, and then the second exposure was performed, and finally the screen was made into a screen printing screen.

Through the above for everyone to briefly introduce how to make screen printing screen steps, hoping to help people who need it.