product description

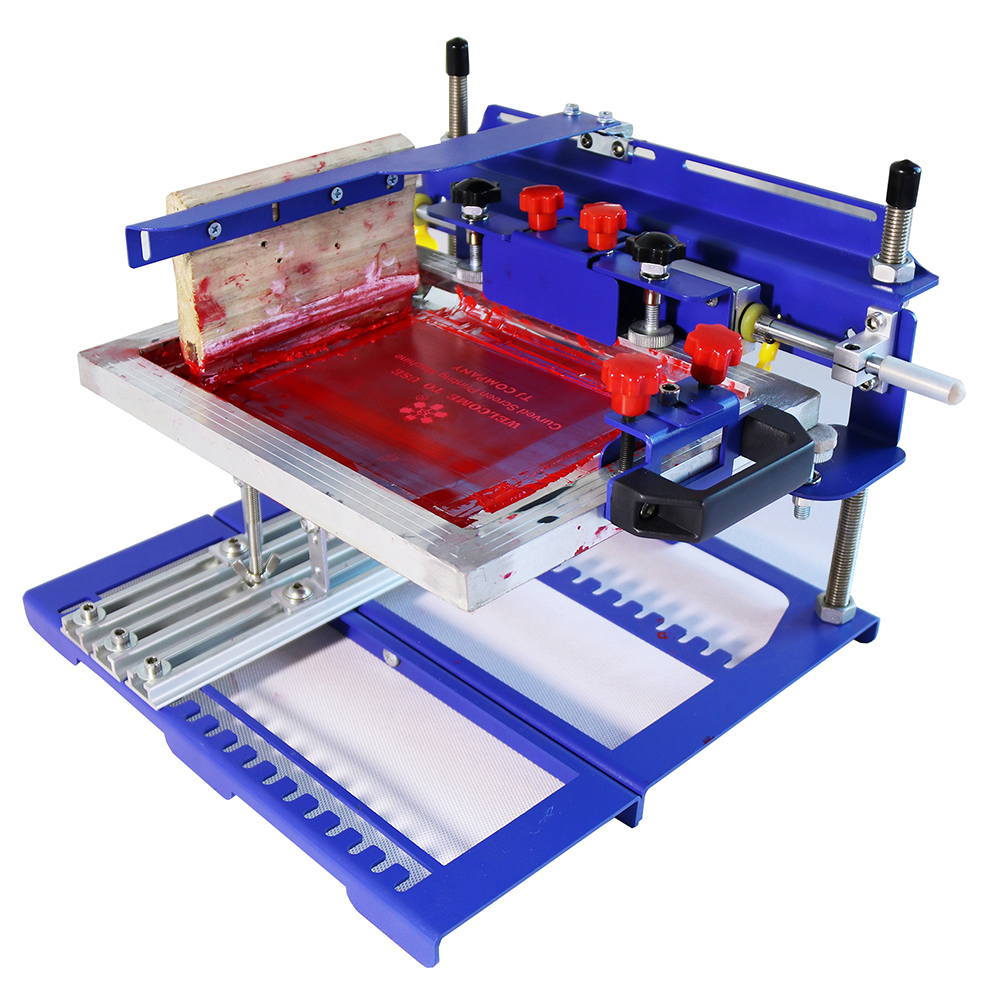

curved screen printing machine is mainly used for the printing of cylindrical and conical products with the diameter below 170 mm.

Product Specification

1.The machine adopts left and right push-pull structure.Installation parts can be adjusted as needed, it is suitable for left or right hand easy operation. Suitable for printing patterns with width less than 200mm; Length less than 150 mm ; Suitable for all kinds of screen plate with the outer diameter less than 260* 450mm and thickness less than 35mm.

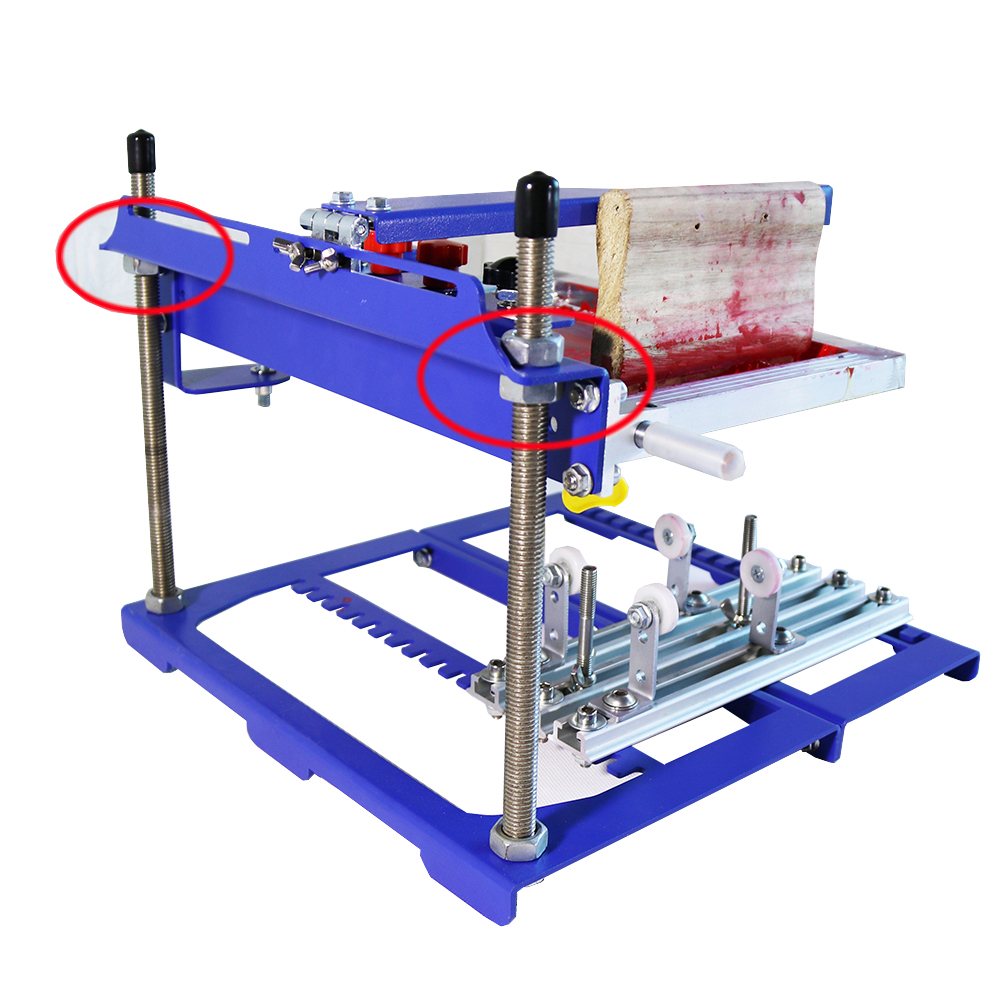

2.the machine is positioned by adjusting the height of the rear main frame , the rear main beam according to the height of the substrate, by adjusting the stand column screw to adjust up and down .The upper and lower adjustment range is 200 mm.It can used for printing cylindrical and conical products with the diameter below 170 mm.

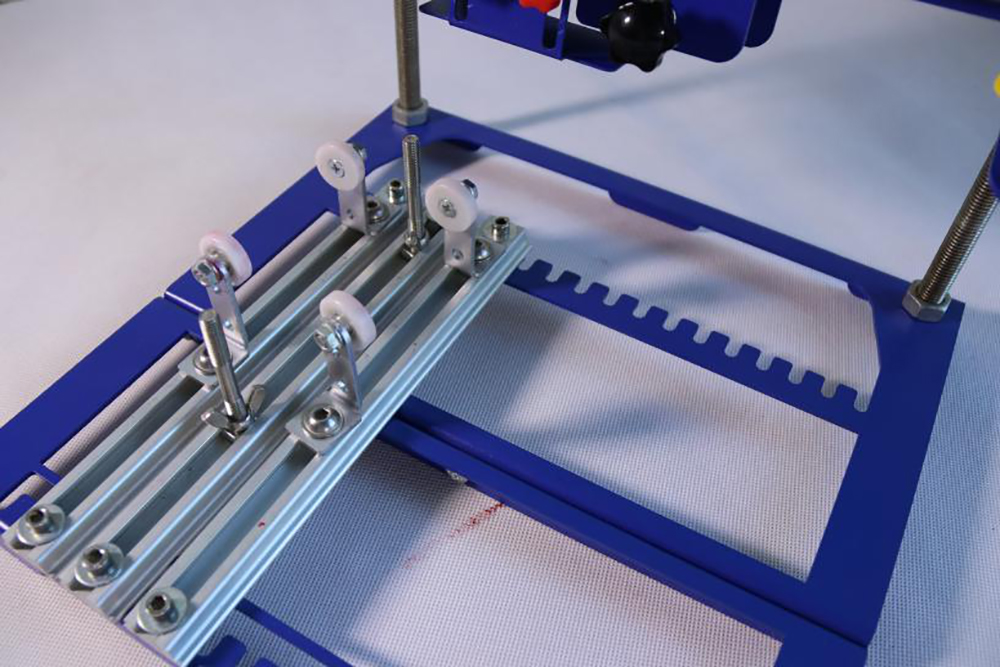

3.Substrate printing rack can move from left to right ,front to rear, three fixed aluminum bar in the bottom can be directly installed on the base, the aluminum bar base can move 290 mm from left to right ; Both sides aluminum alloy strips are substrate placement rack installation strip, the middle is substrate positioning rack installation strip. Three mounting bars can be moved around as needed. Lock position in the base front and rear 19 u-shaped holes (each hole spacing 15 mm), to ensure that the installation strip positioning accurate.

Installation of aluminum bar movement: loosen the screws at both ends of the installation bar . Push the installation strip to the rear of the machine to the long hole of the strip, move the installation strip left and right until it is in a proper position, then pull the installation strip to the fixed U groove .Tighten the screws at both ends to complete the positioning.

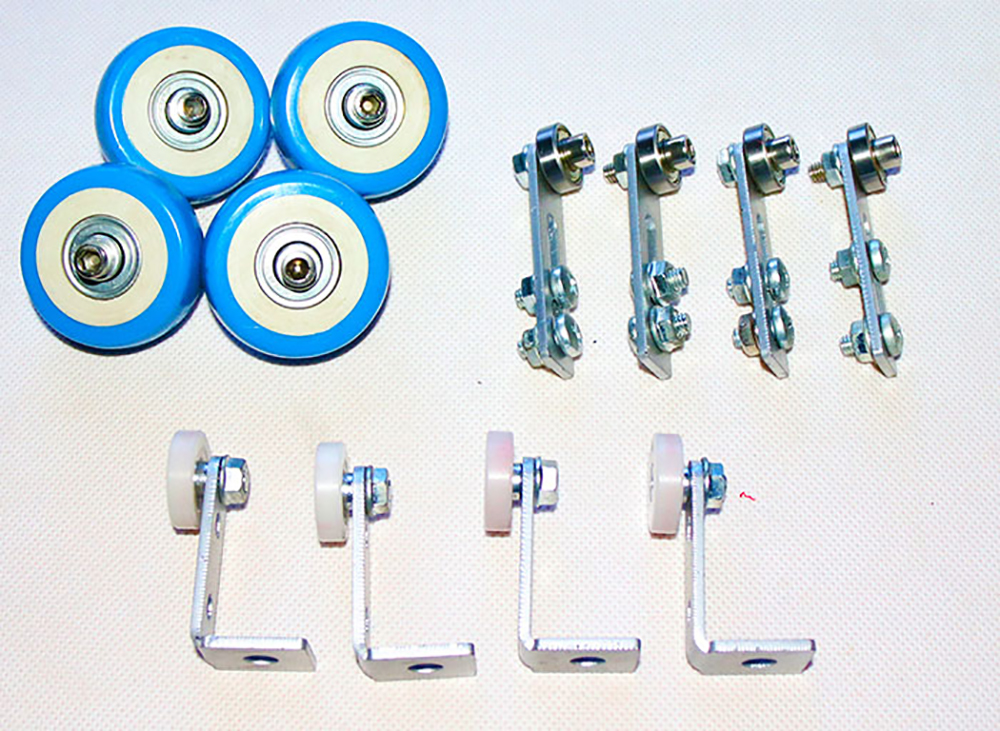

4.Adopts three sets of substrate to place rollers, respectively, metal bearing rollers (diameter of 19 mm); Nylon bearing roller (diameter 25 mm); Plastic bearing roller (diameter 50mm) can be changed according to the user’s needs. Main frame and accessory frame can be installed with three rollers.

The bearing mounting bracket is directly fixed in the hole of the aluminum bar mounting strip. It can move up to 160 mm according to the width of the substrate; 4 additional mounting frames, remove the bearings of the original mounting frame and fix the additional mounting frames on the main mounting frame directly with screws. It is mainly used for printing conical products. Additional mounting frame can move up and down 20 mm.

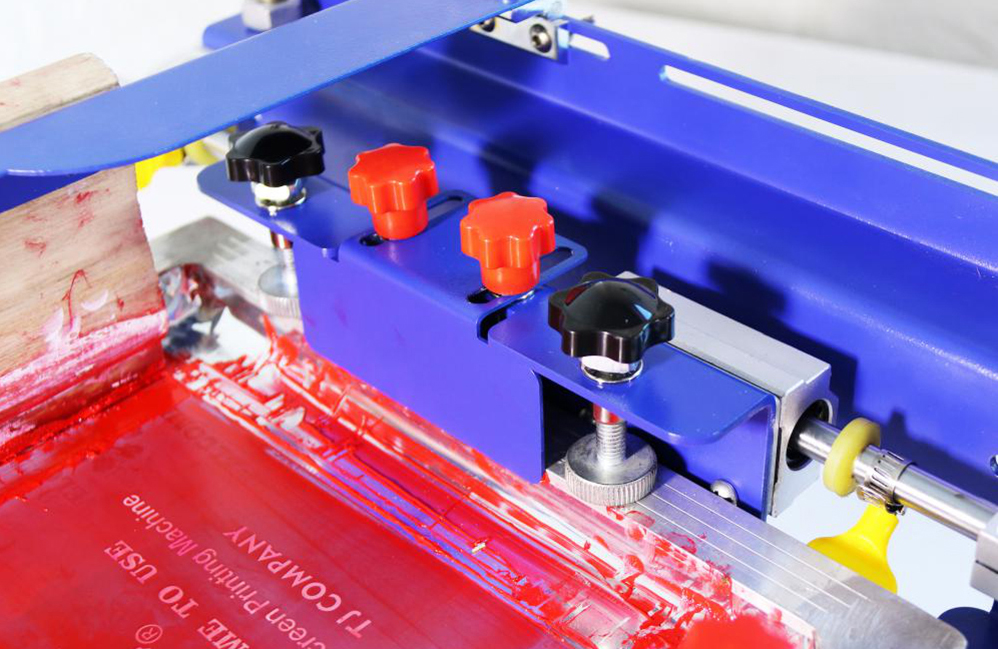

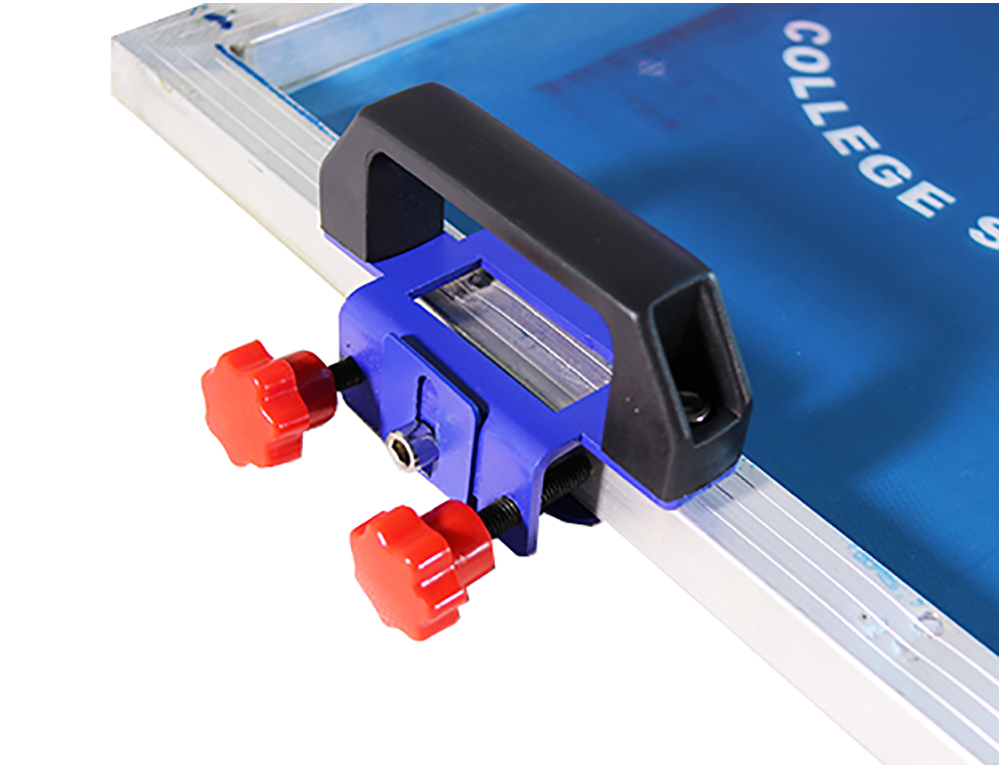

5.The installation of the screen plate is bidirectional fixed, the upper handle fixed screen frame; The baffle in the middle of the chuck is adjusted according to the width of the screen frame. After sticking to the inside of the frame, fix the two handles to fix the screen plate tightly. It can be applied to all kinds of screen plates with high, wide 10-35mm.

6.The screen plate support base is mainly used to support placement of the screen plate after printing , prevent the screen plate falling down when support by hand; The base can be adjusted up and down according to the thickness of the screen plate to suit the best support.

7.the screen frame with a special handle directly fixed on the screen frame, two installation methods, it can be installed in the upper part of the screen frame,it also can be installed on the side of the screen plate,it is easy to push and pull from left to right, the handle can be arbitrarily fixed in any part of the screen frame, the upper red handle and the front baffle fixed screen plate, to ensure that the screen plate firmly fixed on the handle. The handle fits various mesh frames within a thickness and width of 35 mm. 8.Squeegee rack is used for self-tapping wood handle squeegee, and it is suitable for the length of 200mm wood handle squeegee. The rack can be moved about 250mm according to the position of the pattern of the screen plate.

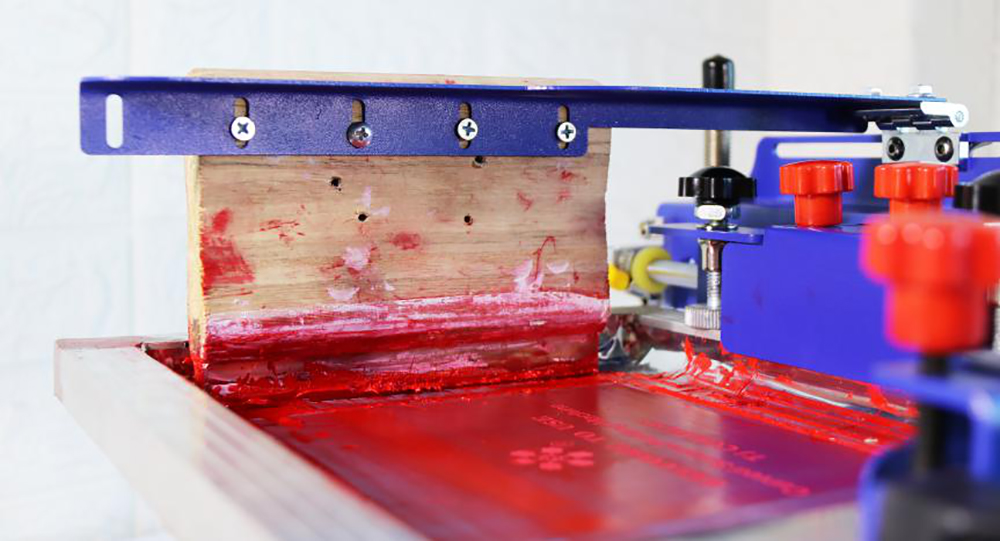

8.Squeegee rack is used for self-tapping wood handle squeegee, and it is suitable for the length of 200mm wood handle squeegee. The rack can be moved about 250mm according to the position of the pattern of the screen plate.

9.The screen plate movement distance positioning; Both sides of the optical axis are equipped with positioning rings and anti-impact rubber rings. The positioning rings are adjusted to the appropriate position according to the pattern size. Anti-impact apron can prevent the metal between the impact of abnormal sound, protect machine parts.

10.This machine can realize the main operation of the left hand by adjusting three parts. Adjust the screen frame handle; Adjust the position of the slider bearing; Adjusting the support base of the screen plate.

Usage

Install the screen plate and adjust the support seat under the screen plate to the basic level of the screen plate; Install screen frame pull handle;

Install the scraper and fix it at a distance of 1-2 cm from the pattern;

Adjust the position of the substrate printing frame and roller bearing, place the substrate, and the spacing between the top of the substrate and the screen plate is 1-3 mm; And make the substrate the top and the bottom of the scraper aligned;

Adjust the distance positioning knob of the screen plate according to the left and right dimensions of the pattern;

Put ink into the screen frame;

Press the scraper with the left hand (or right hand); Pull the handle with right hand (or left hand)on the screen frame to print.

Application

Curved screen printing machine is mainly used for printing cylindrical type, cone type products; Such as a variety of plastic, glass, metal materials made of cylindrical, conical shape products, including wine bottles, medicine bottles, cosmetics bottles and other packaging bottles; Mugs, thermos mugs, beer mugs, red mugs, etc. Glass tube, pen ,ballpoint pen, fishing rod, bat and other small cylindrical products;

For cylindrical or conical type products, the printing surface has a large concave or convex, the printing surface has spots and other non-plane printing is not suitable for the machine.

Our Advantages

–Improve the accuracy of substrate placement, ensure that all printing positions are basically the same after substrate placement

–Substrate placement faster, no need to mark or manually adjust, directly put into the substrate.limit the substrate in the printing process does not deviate.

–The attached plate configured by the machine is used in conjunction with the substrate placement in the main frame, which is mainly used for printing products with conical shape. The attached plate can be connected with the main frame vertically with two screws, or cross connected with the italic body of the main frame with one screw.

–The machine has been fully adjusted before leaving the factory. The customer only needs to install the spring and screen frame landing board for use.

–The main body of the machine uses advanced electrostatic spraying metal surface treatment, acid and alkali resistance, corrosion resistance, clean resistance, no rust, can be used for a long time; Some parts are made of stainless steel and aluminum alloy.

–Equipped with a full set of installation tools and detailed installation instructions; Easy installation without additional tools.

–Export to Europe and America standard fumigation-free wooden box packaging, all kinds of metal parts in the box are individually packaged or placed in isolation to ensure that all kinds of metal parts do not contact directly