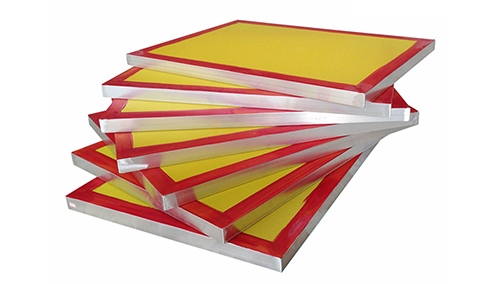

Different fabrics need different meshes. Even if the screen printing process is simpler than other printing processes, there are still many parameters that need to be strictly controlled in order to ensure that the final printing results are accurate. From the screen printing material mesh cloth, mesh, mesh frame to the screen tension data need to strictly control, these are determined according to the requirements of the printing product. Here are just two materials for screen printing mesh.

At present, there are two types of screens used in screen printing: polyester screen printing mesh and nylon screen printing mesh. Although polyester materials have been widely used around the world, most screen printing manufacturers prefer to use nylon screen printing meshes more generally. Screen printing mesh made of polyester material has many characteristics, such as high temperature resistance, solution resistance, water resistance and chemicals. In addition, the polyester material has a unique advantage, that is, when the polyester silk screen printing mesh is subjected to a strong external pressure, its physical properties can make it still stable, very low shrinkage. Compared with screen printing mesh cloth made of nylon material, polyester mesh screen printing fabric also has its disadvantages – the wear resistance is worse than nylon mesh cloth. Because of its dimensional stability, polyester screens such as circuit boards are used. The disadvantage of nylon mesh fabric is just the opposite of the advantages of polyester, so it is not suitable for fine products such as printed circuit boards.

At present, there are two types of screens used in screen printing: polyester screen printing mesh and nylon screen printing mesh. Although polyester materials have been widely used around the world, most screen printing manufacturers prefer to use nylon screen printing meshes more generally. Screen printing mesh made of polyester material has many characteristics, such as high temperature resistance, solution resistance, water resistance and chemicals. In addition, the polyester material has a unique advantage, that is, when the polyester silk screen printing mesh is subjected to a strong external pressure, its physical properties can make it still stable, very low shrinkage. Compared with screen printing mesh cloth made of nylon material, polyester mesh screen printing fabric also has its disadvantages – the wear resistance is worse than nylon mesh cloth. Because of its dimensional stability, polyester screens such as circuit boards are used. The disadvantage of nylon mesh fabric is just the opposite of the advantages of polyester, so it is not suitable for fine products such as printed circuit boards.

Nowadays, the commonly used screen printing mesh materials are known to you for both of them. Both the polyester screen printing mesh material and the nylon screen printing mesh material have their advantages and disadvantages. We hope to bring you both types of screens. The analysis of the advantages and disadvantages of printed materials can help everyone.