As we know, in the process of screen printing, the use of silk screen printing mesh materials is indispensable. There are many kinds of silk screen printing mesh supplies, which can not be summarized in a few words. Many people want to know the classification of screen printing mesh material, here is a introduction of the classification of silk screen mesh materials in screen printing materials, hope you like it.

The classification of screen printing mesh materials

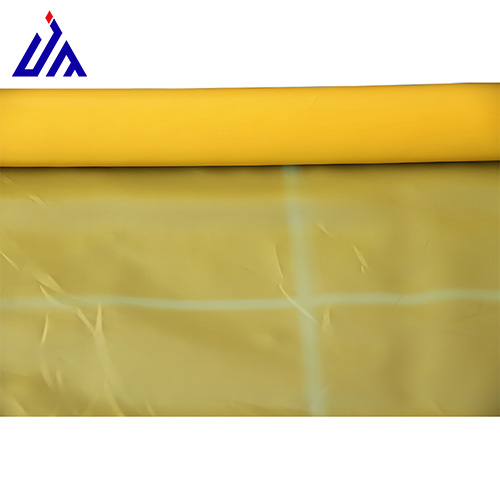

First of all, the nylon material used in daily life is the most commonly used material in screen printing. The wire diameter of nylon mesh is even, and the surface is smooth. It has the characteristics of wear-resisting, high strength and elasticity. The screen printing ink is better through ability.

Cotton screen mesh: the uniformity is poor, the mesh size is different, the shape is different, the pressure is low. As a result, the printing quality and printing effect are not ideal, so it is seldom used.

Polyester mesh: also known as polyester yarn mesh, is also a synthetic fiber. The mesh area and density are even. Its chemical resistance is stronger than nylon wire, and its elongation rate is lower than that of nylon wire mesh. The disadvantage is that it produces static electricity when printing, and its water – bearing aspect is less than nylon.

The above is our brief introduction of the screen printing cloth materials of the classification of materials, hope it have some help for you. With the development of the times, silkscreen printing is a great invention in our country, which needs more modern screen printing materials to improve. Hopefully, more and more of us will get involved in research and development. In addition, if you have requirements of the screen printing mesh supplies, you can check our website, which has the latest and most complete screen printing mesh materials for your choice.