Screen printing precision includes the following two aspects: First, the screen printing line width distortion is small, the line width is 0.05mm; the second is that the screen printing pattern position accuracy is high, the figure length is 500mm. When the position is <0.15mm, there are many factors affecting the accuracy of the above two aspects. From the screen printing to the graphic printing production process, the following factors are important:

First, the choice of screen printing materials and printing materials: including the frame material, wire mesh material, mesh, color and printing properties;

Generally, LY12, LF2 and other hard alloy aluminum square tube profiles are used. The size is 20mm wide and 20mm thick. The four corners are formed by argon arc welding or riveting. The metal frame is highly accurate and dimensionally stable. Currently used most are nylon mesh and polyester mesh. Nylon mesh has poor heat resistance, and it is easy to produce thermoplastic deformation after being heated, which makes the tension uneven and affects the quality of screen printing. Bonding stretch nets or screen stencils are not suitable for high temperature baking. Polyester mesh has good heat resistance and dimensional stability, and the pattern does not change greatly due to changes in temperature and humidity.

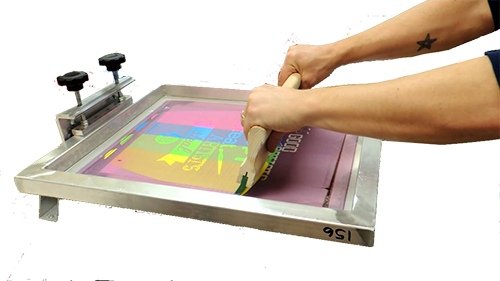

Second, screen printing set equipment deployment, tooling: screen printing machine, positioning tooling, etc.;

Even the same screen printing machine in the printing process, the final silk screen finished product accuracy is slightly different, the positioning tooling changes and deployment will also affect the print accuracy, in the screen and printing materials, different The material of the frame, as well as the mesh number of the screen, the color and even the characteristics of the printing itself, will cause the precision of the screen printing product.

Third, the production process includes stretch net, screen plate making, printing process, etc.;

Stretching net is an unavoidable link. To produce high-precision printed graphics, firstly, the stretch net is required to meet the quality requirements. It is best to use a pneumatic stretcher. The quality requirements of the stretch net are as follows.

1. The tension of the stretcher is suitable and uniform. The tension is as large as possible. If the tension is too large and exceeds the elastic limit of the material, the mesh will lose its elasticity, become brittle or even break. The tension is insufficient and the screen is soft and lacks resilience. It should be considered according to the rated tension and then according to the working conditions, so that the tension on the entire screen surface is uniform.

2, the warp and weft wire remains vertical

The warp and weft of the stretched screen should be as perpendicular as possible to the side of the frame. When the net is stretched, the net is stretched, that is, the force is consistent with the direction of the wire; the second is that the net held by the net can stretch horizontally. mobile.

3, to prevent slack

In order to reduce the tension of the mesh over time, the screen will become loose or looser, and the tension will decrease. The continuous pulling and repeated tensioning of the stretcher should be adopted to make a part of the tension loose before the fixed net.

Fourth, screen printing environmental conditions: screen printing field temperature, humidity, cleanliness, especially cleanliness is an important factor affecting the amount of product;

The use of ink in the screen printing process is very important, and the performance of the solvent in the ink is easily affected by the temperature, humidity and cleanliness of the operation room, especially the cleanliness of the environment, clean and dry at room temperature. The accuracy of the printed matter is much higher than the environment where the temperature is too high or too low and the cleanliness is not high.

Five. People are the most important factor affecting the quality of the project. The operator must have a high degree of responsibility and a high level of skill.

The operator’s proficiency in the use of screen printing inks, responsibility for work and correct attitude to work will directly affect the quality of screen printing. A working attitude is correct, and skilled can control the operation of each step of screen printing. Workers are much more accurate in print quality than workers who have just been working on screen printing.

Improving the precision of screen printing products is the only way to improve the economic efficiency and reputation of screen printing enterprises. For enterprises with poor print quality, they should find their own reasons, improve the process, environment and other factors in time to ensure silk. The accuracy of the finished products printed on the net has been improved.