3 phase power with 24kw

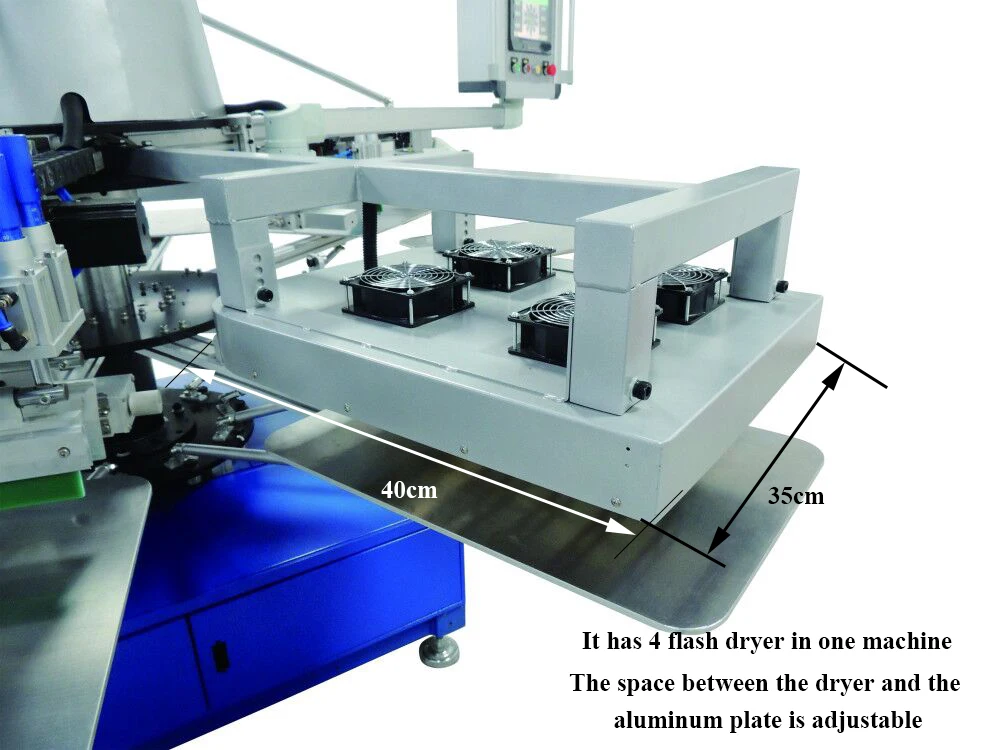

combined with 4 flash dryers 24KW

Laser power and 1 laser marker

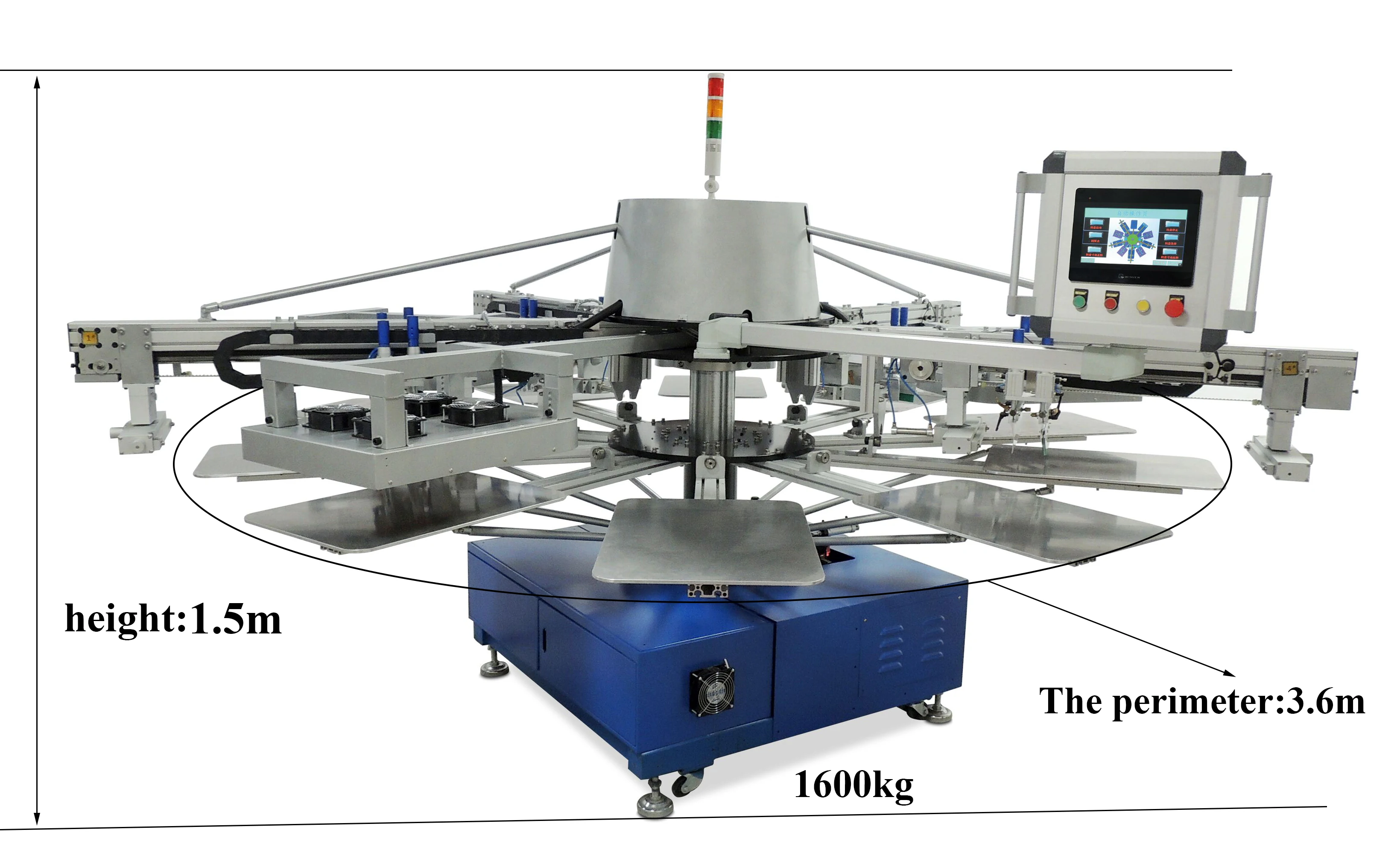

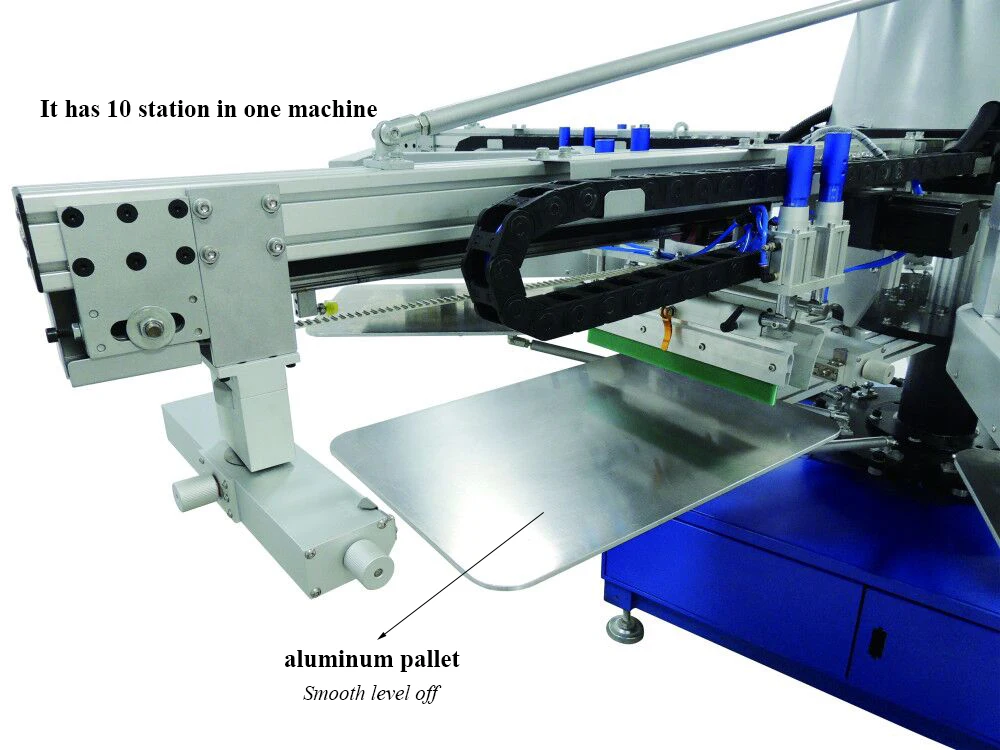

4 color 10 station

10x 18×26′ aluminum pallets

4x 16” squeegees and winged flood bars

Standard print area: 16×20″

Machine diameter 11.64′

Max image size 17×23″ w/ double index mode option of 30×23″

Max frames size 23×32″

Production pieces per hour: 1050

Air Consumption: 10 CFM @ 110PS

Electrical Consumption @ 208 v- 10 Amps Single Phase, 6 Amps 3 Phase

Squeegees with pneumatic or electric movement on everyprint head

AC stepper motor/flood strokes

Independent control panel on all print heads

Central printhead elevation

Servo electro-mechanical indexing system

Individual print and flood controls for speed, height, angle and stroke length

Print heads with high-lift position for quick and easy frame cleaning

Central control panel with LCD touch screen